In a move that could reshape the rare earths extraction landscape, MTM Critical Metals and Meteoric Resources have signed a strategic MoU to advance a breakthrough processing technology for the Caldeira Project in Brazil. The collaboration aims to apply Flash Joule Heating (FJH) to one of the largest ionic clay rare earth deposits in the world—potentially unlocking faster, cleaner, and higher-yield production of critical minerals essential to modern technologies.

Game-Changing Processing Method for Rare Earths

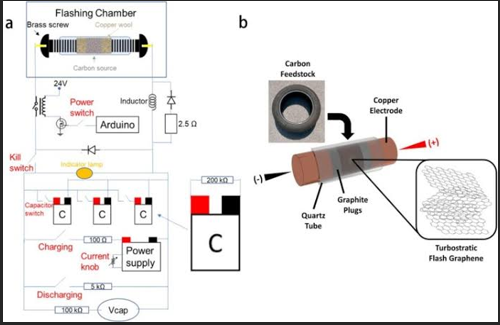

FJH, a rapidly emerging method developed in recent years, involves passing short, high-energy electrical pulses through material—causing a temperature spike that dislodges rare earth elements from the clay matrix in seconds. Early lab trials using samples from the Caldeira Project have already shown significant improvements in recovery rates.

Most notably, terbium recovery surged to 81%, while lanthanum and cerium impurities were reduced, enhancing the magnet-grade rare earth mix—a key component for EV motors and renewable energy systems.

Rare earth-rich ionic clay samples from Brazil’s Caldeira Project

Credit: File

A Strategic Alliance for Future-Facing Mining

Under the signed Memorandum of Understanding, MTM and Meteoric will collaborate on refining FJH for pilot-scale testing and potential commercial deployment. If successful, the method could replace or significantly reduce the need for traditional acid-based leaching techniques that are time-intensive and environmentally challenging.

“This is not just another processing tweak—this could be a true step-change in rare earths metallurgy,” said a spokesperson from MTM.

The Caldeira deposit, located in Brazil’s mineral-rich Minas Gerais region, holds an estimated 1.5 billion tonnes at 2359ppm Total Rare Earth Oxides (TREO)—making it one of the highest-grade ionic clay resources globally.

Also Read: South32 Copper Exploration Pushes Frontiers in Kalahari Belt

What Makes This Different?

Conventional processing of ionic clays often involves multiple leach stages, complex pH adjustments, and long residence times. FJH bypasses much of that through electric-field-induced volatilisation, which unlocks valuable magnet rare earths (Nd, Pr, Dy, Tb) more efficiently.

This not only reduces chemical waste and processing time, but also boosts economic viability, especially in jurisdictions with strong ESG mandates.

Flash Joule Heating test chamber under laboratory simulation

Source: ScienceDirect

The Bigger Picture: Rare Earths and Global Supply Chains

Rare earths—particularly those used in permanent magnets—are central to the global transition toward clean energy, electric vehicles, and advanced defence systems. However, the global supply of rare earths continues to be concentrated among a limited number of nations, with China maintaining a dominant role.

Brazil, with its vast reserves and growing pro-mining policies, is now being positioned as a strategic alternative in the global critical minerals narrative.

If MTM and Meteoric can successfully commercialise FJH for ionic clays, it could trigger a paradigm shift in how emerging-market rare earths are processed—reducing dependency and strengthening geopolitical supply diversity.

Drone view of Meteoric’s Caldeira Project site in Minas Gerais

Source: Meteoric Resources Media Kit

Next Steps: Testing, Piloting, and Scaling Up

The MoU paves the way for:

- Detailed engineering of a pilot-scale FJH unit

- Continuous-flow testing on bulk samples from Caldeira

- Feasibility modelling and scalability assessment

- MREC (Mixed Rare Earth Carbonate) production trials

- Joint intellectual property discussions around technology deployment

While still early-stage, both companies have signalled the intention to move quickly, with pilot programs expected by late 2025.

Analyst Outlook: Potential Disruption in Play

Industry observers see this partnership as one of the most exciting tech-driven developments in rare earths since the rise of solvent extraction in the mid-20th century.

“We could be witnessing the next leap in sustainable rare earth recovery, particularly if the economics scale well,” said an analyst at Critical Minerals Watch.

The prospect of producing MREC with high magnetic rare earth purity and low waste profiles could significantly improve the environmental and financial footprint of these operations—possibly making Brazil a leading hub in the rare earth value chain.