Image: Metso

In a historic first for Australian gold processing, Metso has received a substantial order to supply Australia’s first mobile high-pressure grinding roll (HPGR) circuit—a pioneering move that prioritizes innovation, mobility, and sustainability as the essence of mineral processing.

The NW800HRC™ HPGR plant, powered by Metso’s technology, will be commissioned in an Australian Midwest gold project. It is not just a milestone for Metso—it is a sign of what the future holds for mineral processing: towards flexibility, energy efficiency, and intelligent design.

What Makes This a Big Deal

Source: Metso

While the term “portable crushing circuit” is not exactly exciting news elsewhere in the world except for the mining industry, in its front page material. Until quite recently, HPGR circuits, where ore is crushed under high pressure, were immobile, massive plants. Everybody is aware of their high lower energy input and increased recovery levels, but portability? That’s breaking news in Australia.

This on-site, custom HPGR solution is designed for fast installation and minimal on-site construction, specifically aimed at logistics and remote gold project conditions.

Metso’s NW800HRC™: Built for the New Gold Rush

Credit: Metso

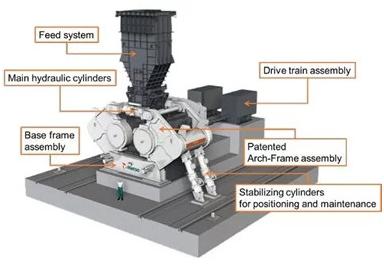

And finally, the gear. Amidst all this technology stands Metso’s NW800HRC™, a high-capacity HPGR system of pre-assembled wheeled modules. It’s designed to be shipped out where needed and provide high-intensity crushing action without the lengthy setup of conventional grinding circuits.

It’s not some space-saver novelty–it’s designed to minimize environmental impact, increase capacity for ore processing, and provide a more civilized in-site operation.

For miners in Australia looking to the challenge of managing varying ore grades, increasing energy prices, and onerous ESG demands, it’s a timely solution.

Cleaner, Leaner, Faster: Why Energy-Efficient Grinding Matters

Processing gold is an energy-intensive business. Conventional SAG (semi-autogenous grinding) mills are infamous power hogs, normally operating at just slightly more than break-even efficiency. HPGRs crush ore with pressure instead of impact, generating finer product at lower energy.

Metso’s mobile configuration maintains that efficiency advantage but goes one step better by enabling miners to place closer to the pit, reduce haulage, and lower their carbon footprint.

Indeed, the firm asserts that the system is among the greenest HPGR options on the market today—something sure to be met with skepticism in the ESG-influenced investment age.

Behind the Scenes: Why the Client Chose Metso

While the name of the operation is not revealed, Metso’s move was by design. Industry observers say it was a mix of Metso’s good global track record, HPGR technology reliability, and localized project delivery ability.

Metso traced its roots all the way back to the Australian mining supply chain. From Mount Isa to Perth, its offerings already reach from lithium to iron ore. And this additional triumph further expands its dominance to future-proof portable grinding solutions.

What This Means for Australian Gold Mining

The gold mining sector is familiar with technology—but it has also had to contend with cost concerns, grade variability, and narrower operating time windows. This HPGR mobile circuit tackles a few of those headaches.

It facilitates modular expansion, becomes more and more feasible for satellite and temporary use, and even lends itself to stage-one testing prior to major infrastructure commitment.

You will notice more miners in WA, Queensland, and the Northern Territory looking at these mobile energy-efficient plants, especially for junior exploration programs and brownfield development.

More Than Just Machines: Mindset Shift

The most thrilling aspect is not machines—it’s a mindset change. The industry is casting off the huge, fixed, high-energy infrastructure and adopting flexible, modular, environment-friendly processing technologies.

In Metso language, this circuit is “a reaction to real field challenges.” And it’s not innovation for its own sake. It’s about adapting fast, keeping downtime to a minimum, and maximizing yield, all the while keeping an eye on carbon emissions and land disturbance.

What’s Next?

With the HPGR unit to be shipped and commissioned in the coming months, all would be anticipating its figures of performance. Going by the initial results so far, it is likely to be a new standard for mobile grinding of gold, copper, lithium, and rare earth ventures.

Metso previously said that this won’t be a one-time occurrence. More modular systems are planned for operation in areas of difficult terrain, difficult-to-get permits, or fleeting project lifespans.

Also Read: Speakman Wants AI in Schools. Here’s What That Means for NSW

End Note: Why This Time Matters

To an industry whose reputation is that of titan-sized fixed facilities and glacial approvals, Australia’s first-ever mobile HPGR circuit is a fresh, welcome-if-grubby breath of air.

It’s a move towards wiser thinking, faster action, and embracing technology that’s as adaptive as the world it’s entering.

Australia’s mining landscape is changing—and Metso just provided it with the tools to do it faster, cleaner, and smarter.