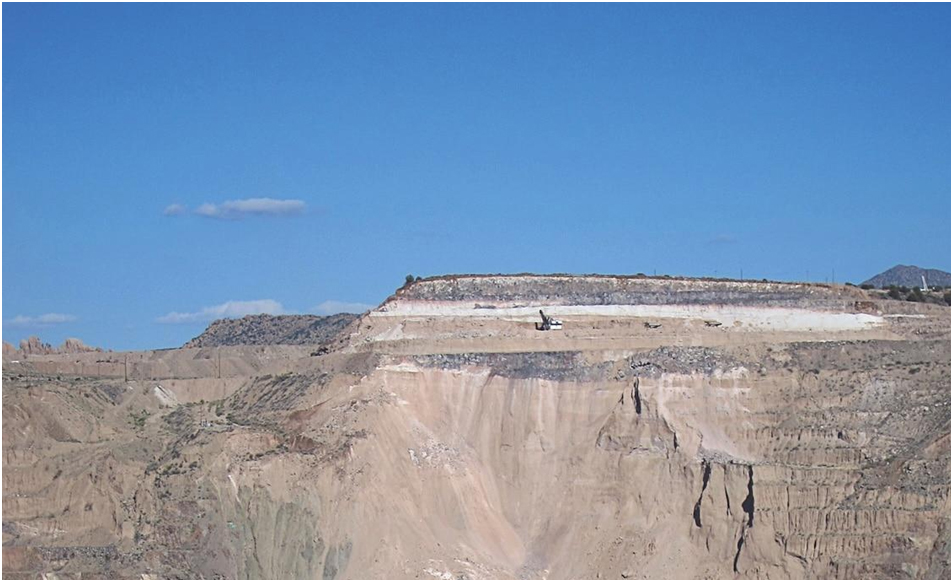

CREDIT: Canary Systems

Summary:

What’s New: Canary Systems has added its slope monitoring suite to enable live alerts and interactive 2D/3D visualizations for enhancing safety in open‑pit operations to its MLSuite platform.

Key Features: Integrates multiple sensor inputs – radar, prisms, piezometers, drones, InSAR – with MLWeb analytics and automated reporting.

Why It Matters: This model turns mining teams from reacting to crises to planning ahead and minimizing risk by using data more intelligently.

Rethinking the Slope’s Safety

For open‑pit mines, a millimetre of unanticipated ground movement can be problematic. Canary acknowledges this with a system that consolidates all the crucial information –– radar scans, prism shifts, pore pressures, drone models, InSAR readings –– on to one unified platform. The outcome? Engineers are no longer flipping between screens or spreadsheets — they are seeing it all live, in 2D or 3D.

What It Includes

1. Sensor Integration

Canary’s tech combines reads from radar, prisms, piezometers, inclinometers, drones, weather sensors and satellite imagery. The outcome: increased accuracy from cross-validation.

2. MLWeb 2D/3D Visualisation

Users can see layered data and tools that show when and where problems began — monitoring changes over time and finding where they have originated.

3. TARP‑Tied Alerts

Personalized threshold alarms alert teams via SMS, email, mobile push, or dashboard pop‑up with raw data.

4. Automated Reporting

Monthly reports including heat maps and trend analysis sets our engineers free to make more strategic decisions.

Proven Results On-Site

Operators at a copper mine cut into ancient volcanic rock went from a clunky process — pulling off individual radar and pore‑pressure logs — to a single dashboard. They’re now able to identify movements of slope up to 48 hours in advance of when the movement would be actuated and take action proactively, minimizing the downtime and the risk of closure.

A mine in Nevada has also deployed MLRemote and MLGPS sensors—these are also now connected to MLWeb. With these, the crew runs nearly 200 sensors off one interface, and the system automatically designates movements that match TARP levels. This eliminated hours of manual monitoring as well as making faster, more accurate responses possible.

Open-pit Mining Operations Supported by Canary Systems CREDIT: Canary Systems

Comparing the Industry

A good example would be Hexagon’s HxGN which integrates radar and prisms into spatial models. IDS Guardian blends radar and GNSS for alert triggering and Leica GeoMoS incorporates total station precision. As Tinkham-Rand points out, what makes Canary so different and unique is it’s vendor agnostic – clients can use their own instruments which are supported by MLSuite, saving time, money, and hassle.

Why We Aren’t Calling it Just Another Tool

● Incredible head start: Canary indicates an incredible 90% of slope failures give tremor advance warning; detecting this early could prevent the entire slope from collapsing.

● Costly delays avoided: a stopped block group could be A$1–5 million a day; catching the issues early helps the team keep safety and cash flow.

● Regulatory ready: with logs, alarms, and archiving, the platform meets compliance standards for geotechnical use in areas such as, Western Australia, Chile, and Canada.

● Exquisite excavation: for example, instead of blasting and putting in massive buffers, mining teams are taking very exact cuts knowing the slope will be stable.

Real-World Gains

Operators deployed in the field told us they are saving themselves a few hours a week of monitoring using ; since implementation of MLSuite. The Geotechnical Team from the University of Arizona also lobbied the mine in celebrating their smart slope technology as a requirement of contemporary mine design.

Rolling Out Globally

The 2025 platform update introduces offline field support and accelerated alert handling. Pilots are scaling in Australia, Chile, and Indonesia. As mines push for deeper benches and steeper walls, Canary’s role in turning slope monitoring from a manual chore into an intelligent, automated system is gaining widespread recognition.

The Underlying Value

What truly distinguishes this technology is its anticipation. Roughly 90 percent of slope collapses show initial movement, but only systems like MLSuite can detect and act on those signs in time. With the proper warnings and imagery, mine operators no longer must play a guessing game. They can shift from reactive shutdowns to proactive management, minimizing downtime and safeguarding their employees.

In addition to cost and operating benefits, the technology also ensures regulatory compliance with increasing requirements. Countries like Western Australia, Chile, and parts of Canada now require complete slope monitoring logs. Canary’s solution not only meets the requirement, it preserves an auditable record of all movement and notifies.

A New Normal for Field Engineers

Before MLSuite, field personnel were accustomed to toggling up to five different software systems and being awakened during the middle of the night by a false alarm. Today, everything is brought together on one dashboard. The system is cell-phone enabled, and it delivers status messages even in low-connectivity environments, while enabling engineers to focus on analysis rather than working at cross-purposes with technology.

What’s Next for Canary Systems

The firm will also bring more upgrades in 2025, including offline capability and increased visual speed. Active field pilotage is in progress in Australia, Chile, and Indonesia, nations where slope stability is paramount due to deep-level mining operations and steep pit walls.

Universities like the University of Arizona are also turning to slope monitoring as the future of sustainable mining. With growing demand and deeper mines, the business can no longer wait for cracks to appear. Prevention is now the norm.

Conclusion

Canary Systems has revolutionized slope monitoring from a disparate, reactive process to a centralised, predictive process. In an industry where failure costs millions, if not lives, this is more than an upgrade in software. It’s a step towards smarter, safer mining.

By integrating multi-sensor data, offering clear and immediate alerts, and simplifying the engineer’s day-to-day workflow, Canary is setting a new benchmark for geotechnical risk management. For mines around the world, this platform isn’t just helpful, it’s a modern necessity.

Read Also : /challenger-gold-mine-great-divide-nsw-adelong