In a bid to optimise overburden movement and streamline dragline operations, an Australian coal mine has adopted AXXIS electronic initiation technology—ushering in a new era of precision and productivity in open-cut mining.

Blasting may be a routine part of surface mining, but behind each detonation lies a complex web of timing, force, and environmental control. For one of Australia’s large opencast operations, that equation just got a strategic upgrade, thanks to the implementation of BME’s AXXIS electronic initiation system—a move that’s already redefining efficiency benchmarks.

Image 1: Aerial view of overburden blasting at an open-pit coal mine

Source: Alamy

The Challenge: Balancing Power with Precision

Open-cut coal mining demands careful coordination—especially in the overburden removal stage. Mistimed or uneven blasts not only increase dozer push requirements but can also lead to coal seam damage, haulage inefficiencies, and reduced equipment uptime.

This mine, located in one of Australia’s premier coal-producing regions, faced exactly that: unpredictable blast results and operational slowdowns caused by conventional initiation methods. Enter BME’s AXXIS system, a digitally controlled solution designed for high-precision blast sequencing.

Why AXXIS Electronic Initiation?

The AXXIS electronic initiation system stands out for its ability to fine-tune blast timing down to millisecond accuracy—allowing engineers to manage energy distribution across large overburden zones more effectively. Unlike traditional non-electric systems, AXXIS is less prone to external interferences and offers complete digital traceability.

For this coal operation, key outcomes have already emerged:

- Improved fragmentation of overburden

- More consistent bench profiles post-blast

- Better dragline efficiency through optimised muckpile placement

- Enhanced safety through remote programming and testing

“AXXIS has given our team the confidence to plan with surgical precision,” said the site blasting coordinator. “It’s not just about power—it’s about control.”

Image 2: Engineers programming blast sequence using AXXIS controller tablet

Source: BME Blasting Systems – Press Kit

Boosting Blasting Efficiency in Opencast Mining Australia

With tighter emissions targets and cost margins, opencast mining in Australia is under increasing pressure to deliver more with less. Blasting remains a critical cost and time lever—and solutions like AXXIS are gaining traction across the sector.

In this case, site managers have reported measurable improvements in blasting efficiency solutions, including reductions in:

- Secondary breakage requirements

- Equipment idling during muckpile clearing

- Dust and vibration levels—supporting compliance with community and environmental standards

Coal Seam Protection Through Precise Initiation

Another standout benefit? Coal seam protection. By tailoring initiation sequences based on geology and blast geometry, the site has significantly reduced instances of seam dilution and coal loss.

This is particularly important as high-quality seams are becoming increasingly difficult to mine without introducing contamination or excessive handling.

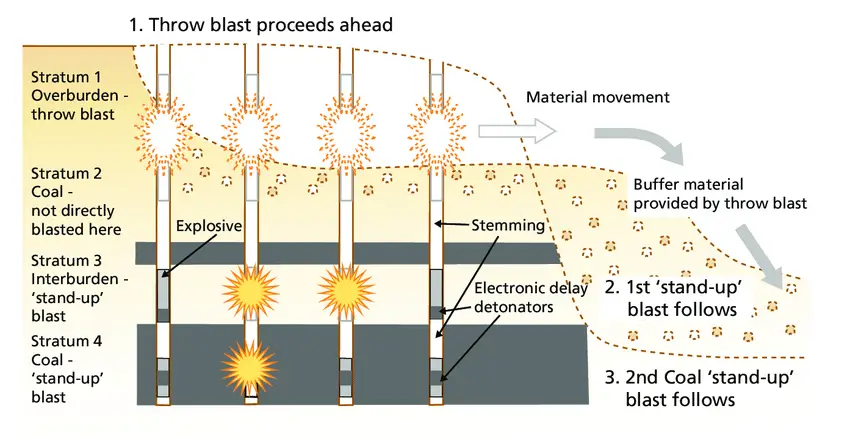

Image 3: Cross-section diagram showing overburden blast profile and protected coal seam

Source: [ResearchGate]

Overburden Movement and the Dozer Push Dilemma

In large-scale coal operations, overburden movement is often the bottleneck between blasting and extraction. Traditionally, ineffective blasts require extensive dozer push—adding labour costs, fuel usage, and equipment wear.

AXXIS enables consistent heave and directional movement, which in this case has dramatically reduced dozer push requirements. The outcome is a smoother transition from blast to dragline to loadout—streamlining the full extraction cycle.

Eliminating Dozer Push: Not Just a Dream

While “zero dozer push” may sound aspirational, that’s precisely the direction the site is heading. By pre-conditioning the overburden through staged initiation, the operation now reports dozer requirements have fallen by more than 30% on some benches—freeing up resources for higher-value tasks.

This kind of outcome illustrates the broader promise of electronic initiation mining systems: they offer tangible, data-driven ROI on even the most basic mine functions.

Looking Ahead: A Template for Other Sites

The success of AXXIS in this project could become a blueprint for other Australian mines navigating rising costs and environmental scrutiny. As miners seek smarter ways to scale production while preserving margins, programmable electronic systems are expected to become standard rather than specialised.

Already, discussions are underway to expand AXXIS usage into satellite pits within the same mining complex.

Conclusion: Smarter Blasting Drives Smarter Mining

The adoption of AXXIS electronic initiation isn’t just about better explosions—it’s about building a foundation for consistent performance, safety, and long-term efficiency in Australian mining.

With more sites watching this pilot closely, the industry may soon shift from reactive blasting to predictive, tech-led strategies that protect resources, budgets, and the environment—all in one coordinated detonation.