Metso has entered into a significant three-year agreement with BHP to provide custom-engineered chute liners and wear solutions across its Western Australia Iron Ore (WAIO) operations, reinforcing its role in advancing maintenance performance across key mining infrastructure. The agreement covers design, manufacturing, and installation of Metso’s proprietary XAlloy™ liners—known for their high durability in aggressive wear environments—alongside advanced cast solutions aimed at improving operational efficiency and reducing maintenance downtime.

Metso XAlloy chute liner installed at WAIO operations – internal view of metallic wear lining. Credit: Metso

Strategic Scope of the Contract

Metso will provide chute liners and related services to multiple WAIO processing plants and bulk handling facilities. This contract demonstrates BHP’s ongoing investment in advanced, lower-maintenance wear technologies that align with its strategy in the Pilbara region.

Key Contract Details:

- Contract Duration: 3 years (2025–2028)

- Coverage: Multiple BHP WAIO sites

- Products Included:

- XAlloy™ metallic liners for areas subject to high impact

- Complementary cast wear solutions

- Full delivery, fitment, and installation support

- Focus Areas:

- Enhanced maintenance efficiency

- Fewer liner replacements

- Improved plant availability

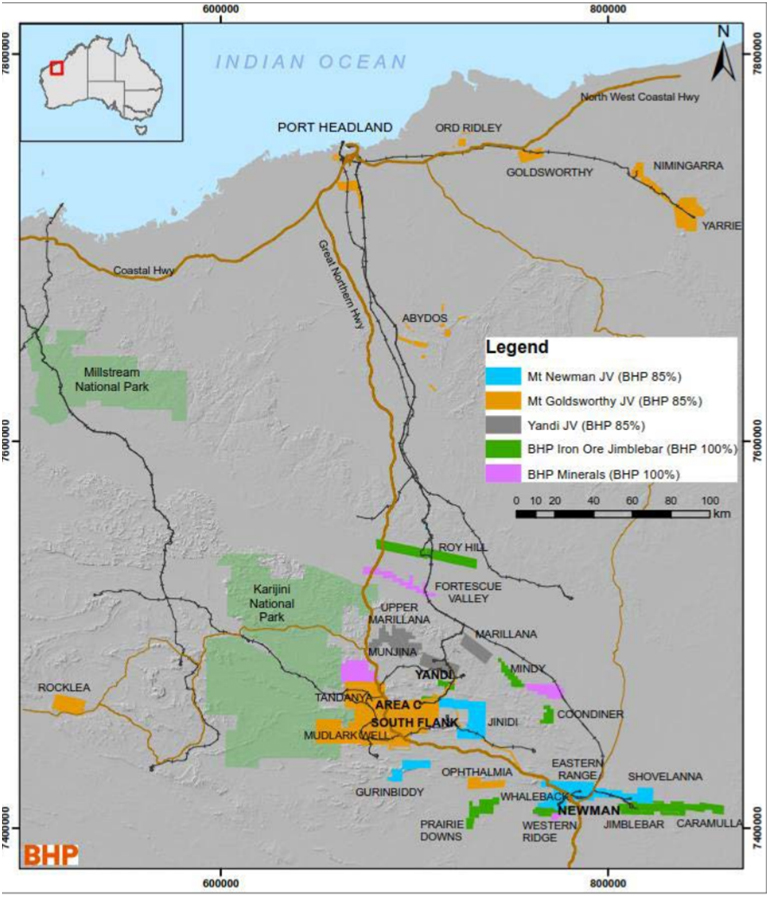

Overview map of BHP WAIO operations in Pilbara with labeled processing hubs. Source: BHP

Also Read: Polymetals Advances Commercial Production at Endeavor Mine

XAlloy™ Liner Technology: Wear Solutions Redefined

Metso’s XAlloy™ chute liners are specifically engineered to resist extreme abrasion and impact—common challenges in high-tonnage iron ore handling operations like those at WAIO.

Advantages of the XAlloy™ System:

- Extended Lifespan over traditional steel liners

- Modular Replacement (Xlok™): Allows single-bolt, inside-chute replacement—no hot works

- Lower Downtime: Faster maintenance with fewer shutdowns required

- Enhanced Safety through reduced exposure in confined spaces

- Live Monitoring: Real-time monitoring is enabled through Metso’s WearSense™ system, which supports condition-based maintenance by detecting wear levels during active operations.

Cross-section of XAlloy liner system and Xlok mounting mechanism. (Metso)

Local Support via Karratha Service Centre

A key differentiator in this contract win is Metso’s strong Pilbara presence, anchored by its Karratha Service Centre—the largest of its kind within Metso’s global footprint.

Karratha Service Centre Highlights:

Size: 35,000 m² site with a 5,000 m² advanced workshop

Capabilities:

Fabrication and refurbishment

Heat treatment and machining

Onsite liner preparation and dispatch

Personnel: 60+ skilled staff supporting WAIO delivery

Turnaround Time: By sourcing components locally, Metso shortens delivery schedules and helps lower logistical expenses, ensuring faster service responses to WAIO sites.

This close-proximity service hub enables just-in-time liner delivery and rapid-response support for shutdowns, further aligning with BHP’s strategy for reliable, low-risk supply partnerships in the region.

Maintenance Efficiency and Strategic Alignment

With hundreds of millions of tonnes processed across WAIO each year, BHP stands to benefit significantly from reduced liner failure rates and more predictable maintenance cycles. The XAlloy-based wear system is expected to contribute:

- 20–30% longer liner life in high-impact applications

- Up to 40% reduction in liner changeout hours

- Enhanced production uptime across ore handling systems

Metso’s focus on engineered wear solutions aligns with BHP’s broader innovation and sustainability goals, particularly in minimising environmental impact, improving safety, and maximising throughput with fewer shutdowns.

What It Means for Metso Australia

This contract reinforces Metso’s market leadership in material flow and wear solutions across the Australian mining landscape. It also signals the company’s continued success in pivoting toward service-based, recurring-revenue models through long-term equipment support agreements.

Marking one of Metso’s largest regional contracts in 2025, the BHP WAIO agreement also strengthens the profile of Metso Australia as a core contributor to global mining performance. It follows a year of rapid growth in Life Cycle Services, which saw more than 100 new global contracts signed across mining and aggregates.

Conclusion: Wear Innovation Fuels Mining Scale

Metso’s new contract with BHP is more than a product supply agreement—it’s a strategic partnership focused on performance, efficiency, and innovation. With XAlloy liners being deployed across BHP’s WAIO network, the company is set to gain from stronger equipment reliability and streamlined maintenance cycles, while Metso strengthens its position as a trusted wear solutions partner in Western Australia’s high-growth mining region.

With support from the Karratha Service Centre and a next-gen lineup of modular liners, Metso is well-positioned to drive the next wave of maintenance excellence for BHP and beyond.