A New Benchmark in Iron Ore Processing

In collaboration with a progressive Indian steelmaker, FLS has rolled out an advanced iron ore beneficiation system aimed at tackling the region’s surplus of low-grade iron ore, establishing a new benchmark in processing efficiency and resource recovery.

Commissioned in early 2025, the project aims to transform extensive reserves of low-grade iron ore into premium-quality material optimised for steelmaking through advanced FLS iron ore beneficiation technology. By leveraging a sophisticated FLS flow sheet, the plant is expected to redefine how the Indian mining sector processes ore in the face of declining ore grades and rising demand for steel.

Source: Engineering & Mining Journal

Source: Engineering & Mining Journal

From Low Grade to Premium Steel Feed

India’s iron ore landscape is increasingly dominated by lower-grade reserves, often below 58% Fe content. Yet steelmakers are demanding higher-grade iron ore for efficiency, lower emissions, and improved product quality.

This is where FLS’s iron ore beneficiation solution becomes transformative. The plant incorporates:

- A custom-engineered flow sheet optimised for ore variability

- 18 vertical tower mills for ultra-fine grinding

- Froth flotation and advanced slurry transport systems

- Integrated mechanical monitoring for predictive maintenance and reduced downtime

The setup delivers unprecedented operational flexibility, enabling the plant to process different ore types, including blends and fines, while consistently outputting ore of 65% Fe or higher.

“This solution is designed not just for throughput, but for adaptability,” said Dylan Brown, Head of Project Engineering at FLS. “The system can respond to feed variations in real time—something few beneficiation plants can achieve at this scale.”

Operational Flexibility: The Future of Ore Processing

At the heart of this project is the push for flexibility in beneficiation, a trend reshaping how miners approach ore variability. FLS’s system allows the operator to shift seamlessly between ore types—whether hematite, goethite, or magnetite blends—without compromising output quality or recovery rates.

This versatility is a key requirement for progressive Indian steelmakers, who face increasing logistical and environmental constraints in sourcing high-grade ore.

“This plant enables our partner to produce world-class feedstock from ore that was once considered uneconomical,” said Brown.

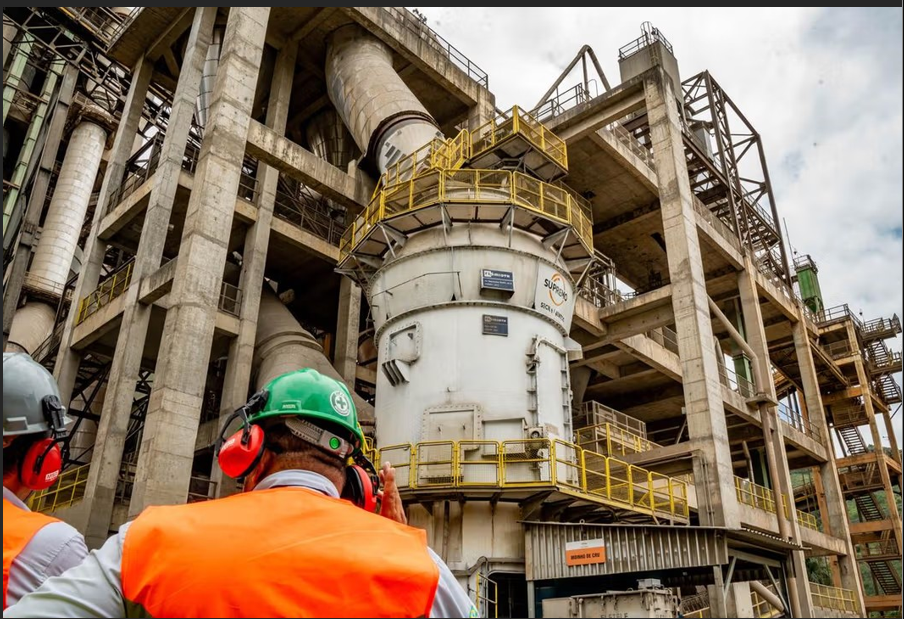

Engineers overseeing slurry transport and flotation processes at the beneficiation site.

Source: Ausenco

Inside the Technology: What Makes FLS’s Flow Sheet Unique?

FLS’s flow sheet integrates crushing, fine grinding, classification, flotation, and filtration into a streamlined circuit. The inclusion of 18 vertical tower mills sets the plant apart, offering high-efficiency milling with a compact footprint.

The system also incorporates state-of-the-art slurry transport networks and froth control mechanisms, reducing water use and energy consumption—two major priorities in modern mineral processing.

A suite of mechanical monitoring tools tracks mill performance, wear rates, and pump efficiency, feeding into predictive models that help reduce unscheduled maintenance events.

A Strategic Win for India’s Steel Sector

Although India ranks among the top global steel producers, its capacity for effective iron ore beneficiation has not kept pace with rising demand, especially in processing low-grade iron ore into high-quality feedstock. As low-grade ores become more common and environmental pressures mount, upgrading beneficiation infrastructure has become essential.

This project sets a new benchmark—not just in terms of technology, but also in demonstrating how strategic partnerships between global tech leaders like FLS and local miners can drive transformational change.

It also aligns with India’s push for self-reliance in steel-grade ore, reducing import dependencies and improving domestic supply chain resilience.

FLS engineers inspecting mechanical monitoring systems integrated into tower mills.

Source: FLSmidth Technical Reports

What’s Next?

The plant is now operational and expected to process millions of tonnes of iron ore annually, delivering a consistent pipeline of premium feedstock to downstream steel plants. FLS is reportedly in discussions with other Indian mining majors for similar deployments.

With rising demand for green steel and increasingly stringent ore quality benchmarks, the success of this project could set the tone for future beneficiation investments across Asia and beyond.

Conclusion: A Giant Leap for Iron Ore Innovation

FLS’s latest delivery represents more than a technical milestone—it’s a step forward in how the world thinks about low-grade ore. By turning previously overlooked resources into high-value product, FLS is helping shape the next chapter of iron ore beneficiation—one that’s smarter, more sustainable, and more globally competitive.

For the Indian steel industry and FLS alike, this marks a critical turning point in aligning mineral processing innovation with future-facing infrastructure needs.